Flexible, independent and fast

Our new machinery

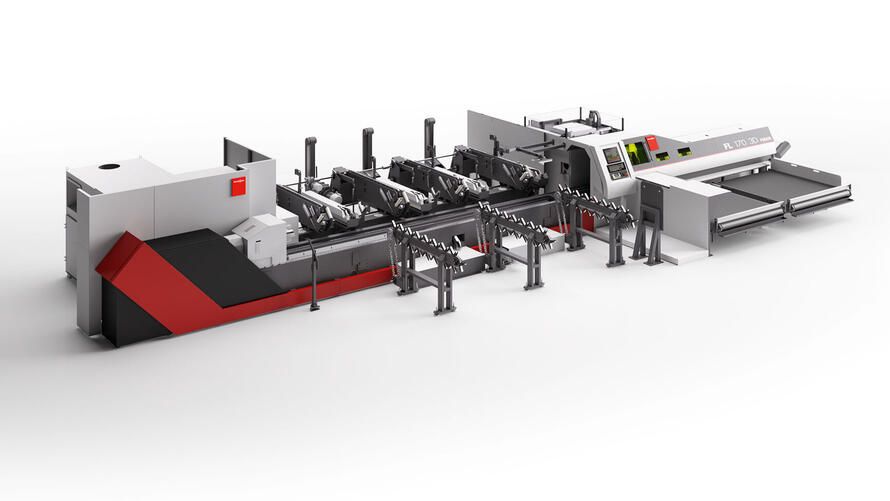

Tube laser

Incl. 3D laser head

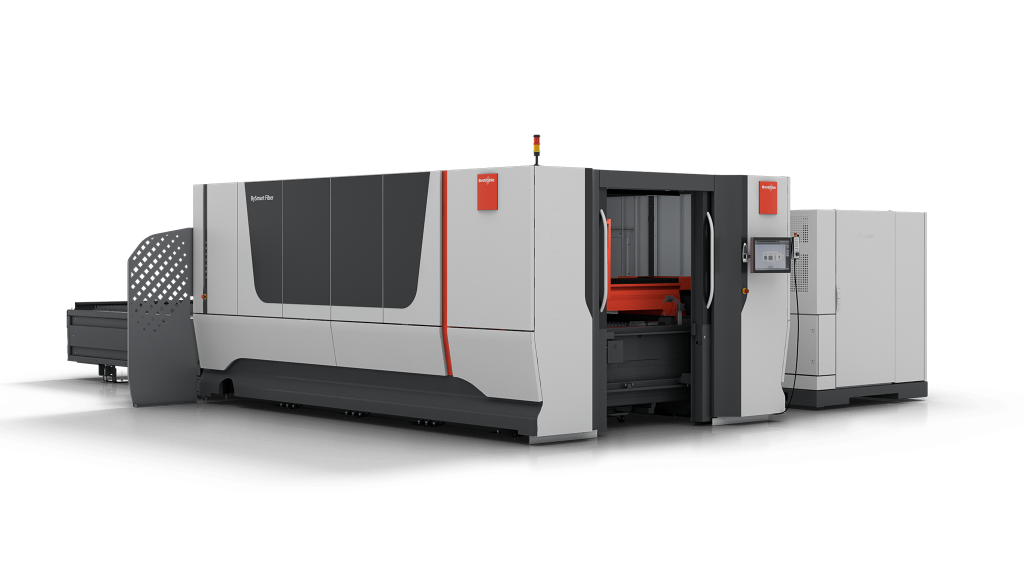

Flatbed laser

fiber laser

Press brake

high-precision & automated

Ready for the future

Everything’s new since 2022

We have expanded our production hall and invested in new, state-of-the-art machines. Every centimeter of the hall has been meticulously optimized for the use of the new systems, so that a perfect material flow and short work routes are guaranteed.

The new machine hall is directly connected to our production and feeds it with perfectly prepared material in the shortest possible way. We do all the cutting here with a flatbed and a tube laser and then bend the parts. With the tube laser, all drilling work, regardless of the shape, can now be completed in a matter of seconds.

Feeding the tubes

Feeding the tubes Bystronic tube laser with chain loader

Bystronic tube laser with chain loader Operation of the tube laser

Operation of the tube laser Cutting center with material

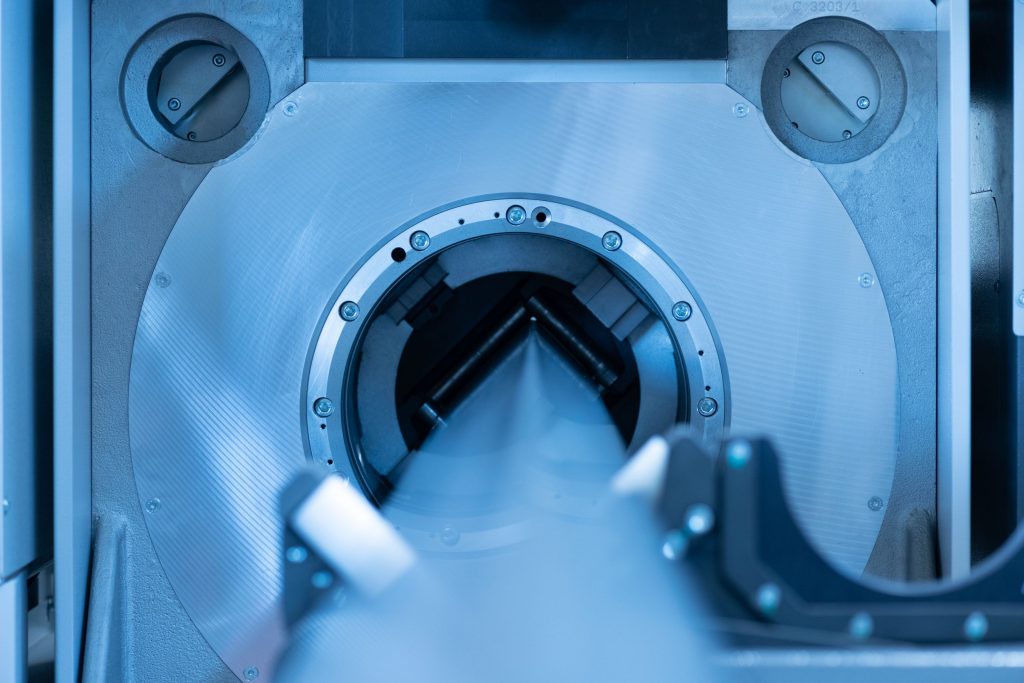

Cutting center with material On-site self-generation of nitrogen from compressed air, powered by solar energy

On-site self-generation of nitrogen from compressed air, powered by solar energy Platform over flatbed laser

Platform over flatbed laser

Mechanical machining

Modern CNC machines

We have several 5-axis machining centers from manufacturers AXA and Hermle in use. Together with our sister company Weimar Werk GmbH , we offer a very high level of vertical integration (including a modern paint shop) and the capacity for large-scale projects.

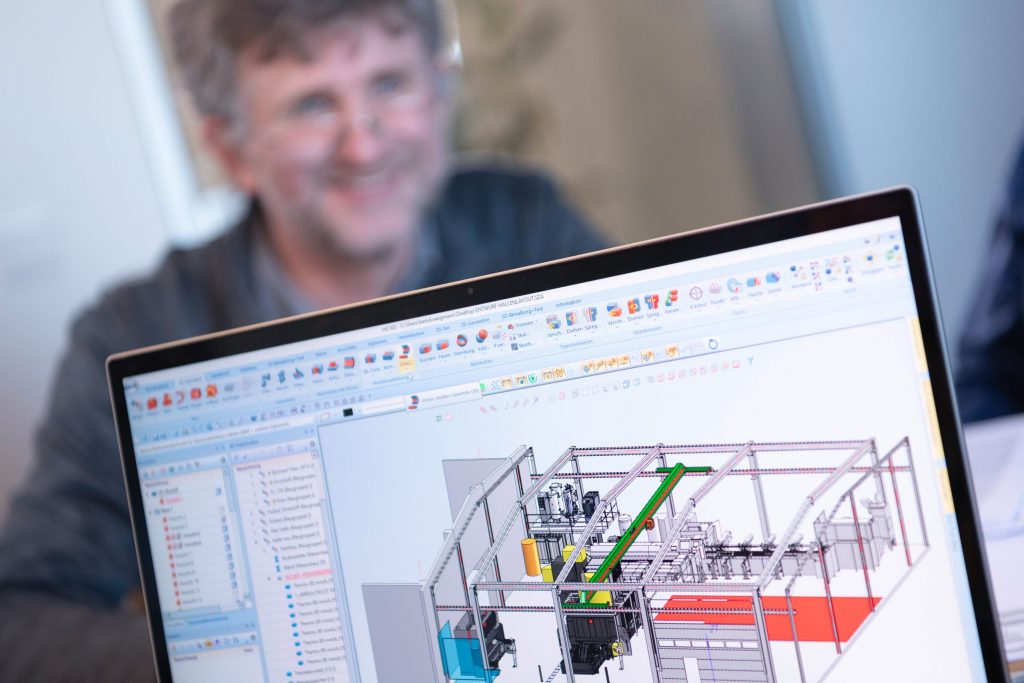

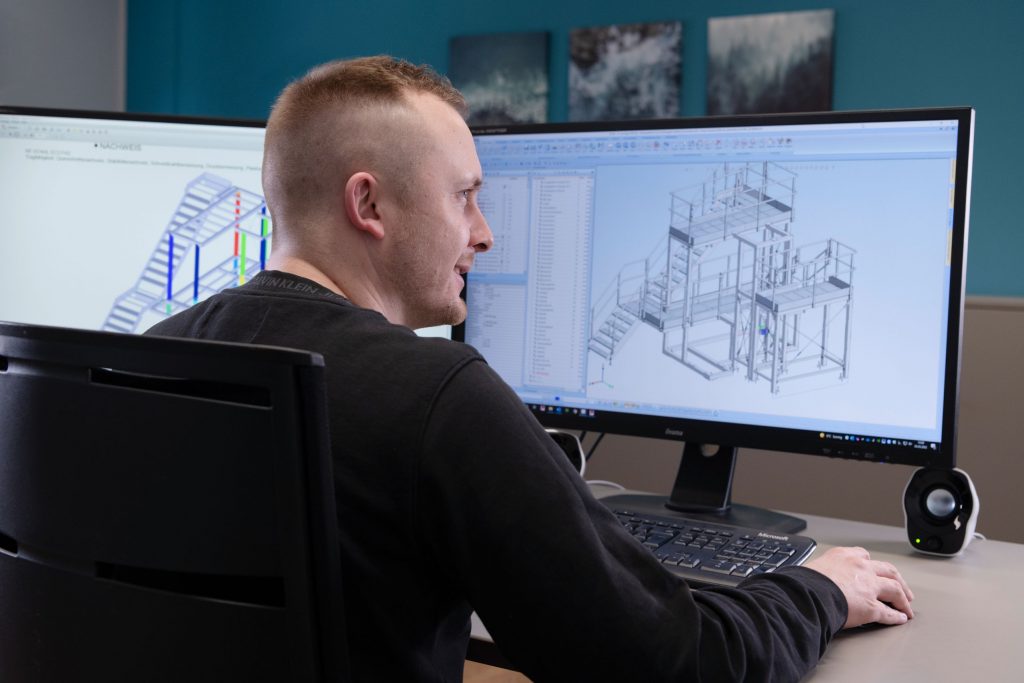

Digitalized

Engineering and automation

In order to really exploit the potential of the new machines, modern work processes are required in design and construction. All machines are connected via the Bystronic software, which makes many processes much simpler. We have also developed some IT automatisms that take care of repeat processes that occur specifically in our company at the push of a button. We design with the 3D CAD software HiCAD, which, in combination with the Bystronic software, enables a smooth workflow. We use MicroFe for our internal static calculations.

Sustainability

on-site nitrogen self-generation

No greenwashing, but a real win-win solution: We use our nitrogen self-generation to operate our new laser cutting systems. The solar power from the roof of our new machine hall is used to convert compressed air into pure nitrogen. This lowers the costs for us and the environment. In addition, we are independent of suppliers and always able to work. With our six gas bundles, we can convert and store around 1000 kWh of electricity into nitrogen – over a sunny weekend this happens using only solar power.

01.

Independent

We can now do the entire cutting including bending and drilling work ourselves. This saves time and money, especially in economically uncertain times.

02.

Fast

Sawing and drilling jobs that used to take a week can now be completed in a few hours. This reduced our processing time by a few days.

03.

Efficient

By reducing the overall cutting times, we can now lasercut the sheets and profiles for entire projects in one go. This also significantly reduces waste.

04.

Precise

By simulating the programs, sources of error are eliminated before production. Welding seam preparation and our modular system bring all parts perfectly into production.

Tube laser in action

Pictures from the new hall

Watch the video of our cooperation with Bystronic and get an insight into the new machine hall. This is what stainless steel manufacture looks like in 2022!

Interested in our new cutting center? Ask our expert!